Processes

The right processes and technology for your product.

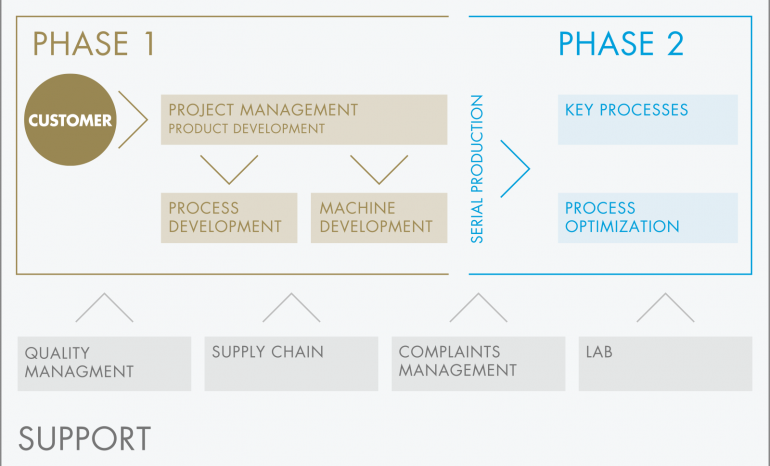

Our comprehensive service and our advisory expertise enable us to partner you from the concept to the finished component, allowing you to benefit from our specialist know-how. What truly sets us apart is our ability to put our springs and stampings expertise to use advising you in the development of your application and then to define the right process and technology for your product. We deliver exactly the functionality and quality you need at optimum cost.